Products

Featured Products

- PE battery separator has higher pore volume

- PE battery separator has lower electrical resistance

- PE battery separator has lower acid displacement

- Optimal pore size distribution for controlled oxygen transfer

- PE battery separator has lower electrical resistance

- PE battery separator has lower acid displacement

- Optimal pore size distribution for controlled oxygen transfer

- PE+GM battery separator is a composite battery material specially engineered for extra heat and oxidation resistance as such, it may be termed as ‘Tropicalised Separator’ highly suited for high temperature abusive conditions.

- PE+GM battery separator with the unique glass fiber-polymer integration affords additional elements of plate protection and extended battery life.

- PE+GM battery separator with the unique glass fiber-polymer integration affords additional elements of plate protection and extended battery life.

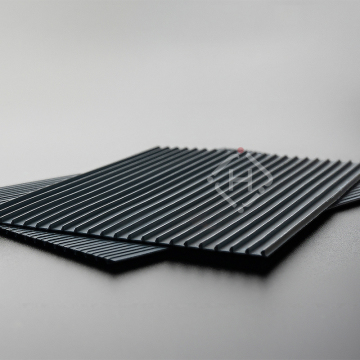

- PE battery separator roll's mini ribs design makes the positive plate maintain more electrolytes, while negative plate keeps definite exhaustion, which can improve battery's performance.

- PE battery separator adapt to lead acid battery, traction batteries, stationary batteries,etc.

- PE battery separator adapt to lead acid battery, traction batteries, stationary batteries,etc.

1. PE Battery Separator Sleeve with mini rib inner and outer.

2. PE Battery Separator Sleeve with smooth surface outer and straight rib inner.

3. PE Battery Separator Sleeve with twill rib outer and mini rib inner.

4. PE Battery Separator Sleeve with traight rib outer and mini rib inner.

2. PE Battery Separator Sleeve with smooth surface outer and straight rib inner.

3. PE Battery Separator Sleeve with twill rib outer and mini rib inner.

4. PE Battery Separator Sleeve with traight rib outer and mini rib inner.

- PE battery separator envelopes' unique formulation results in increased puncture strength, low electrical resistance, high oxidation resistance and low water loss.

- PE battery separator envelope offers advanced technology and unmatched customization to exceed your requirements in the toughest applications. Available in straight, diagonal and s-rib profiles.

- PE battery separator envelope for lead acid battery can be laminated with glass fiber mat that extends battery life under arduous operating conditions such as high ambient temperatures and severe vibration.

- PE battery separator envelope offers advanced technology and unmatched customization to exceed your requirements in the toughest applications. Available in straight, diagonal and s-rib profiles.

- PE battery separator envelope for lead acid battery can be laminated with glass fiber mat that extends battery life under arduous operating conditions such as high ambient temperatures and severe vibration.

- PE+GM battery separator sleeve is offered either with glass tissue or with special cast ribs or with both.

- PE+GM battery separator sleeve's thickness range varies from 0.3mm (only base web) to 4.5mm including rib and glass mat.

- PE+GM battery separator sleeve's ribs come in both straight and sinusoidal shape.

- PE+GM battery separator sleeve's thickness range varies from 0.3mm (only base web) to 4.5mm including rib and glass mat.

- PE+GM battery separator sleeve's ribs come in both straight and sinusoidal shape.

- PE+GM battery separator envelope can completely wrap the battery plate.It is beneficial to prevent the battery from short circuit due to the falling off of active substances or the change of the relative position of positive and negative plates.

- PE+GM battery separator envelope's cast rib process permits a high degree of product customization for specific battery applications such as automotive and industrial including gel batteries.

- PE+GM battery separator envelope's cast rib process permits a high degree of product customization for specific battery applications such as automotive and industrial including gel batteries.