How much do you know about EFB and AGM batteries?

When it comes to batteries, we have to say the car start-stop system. That is, when the vehicle is temporarily stopped (such as waiting for a red light) during the driving process, it will automatically turn off. A system that automatically restarts the engine when it's time to move on.

When the engine is started, due to the need for ignition and the need to supply power to the starter motor, the on-board battery must be capable of high current discharge performance. Since the start-stop system frequently restarts the engine, the battery supports frequent high-current discharges. When the hybrid system provides power to the wheels, the battery needs to provide energy support, which can meet the needs of electrical equipment such as in-car audio and lighting. When the on-board charger charges the battery, the battery must have a strong charge acceptance performance, and the AGM and EFB batteries can meet the needs of the start-stop function.

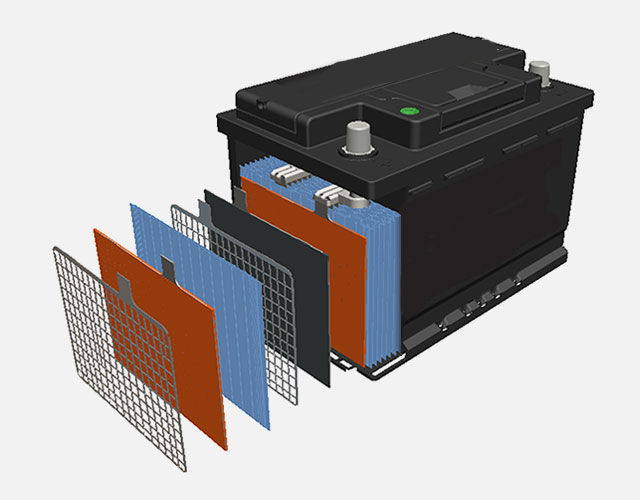

EFB battery

EFB stands for Enhanced Flooded Battery Technology. EFB battery is based on traditional battery technology, by adjusting the active material formula to improve the deep cycle performance of the battery. In addition, the enhanced assembly strength of the inner pole group allows the battery to have a longer lifespan and stronger shock resistance.

EFB batteries can meet the needs of modern vehicle power systems, such as start-stop systems, and provide sufficient energy for more additional electrical equipment (such as navigators, etc.). Compared with traditional batteries, EFB batteries use a unique reinforced lead paste formula. The fiber film of the positive plate replaces the original lining paper to prevent the active material of the battery from falling off, extending the deep cycle life of the battery by more than 2 times. Greatly improve the battery's charging acceptance.

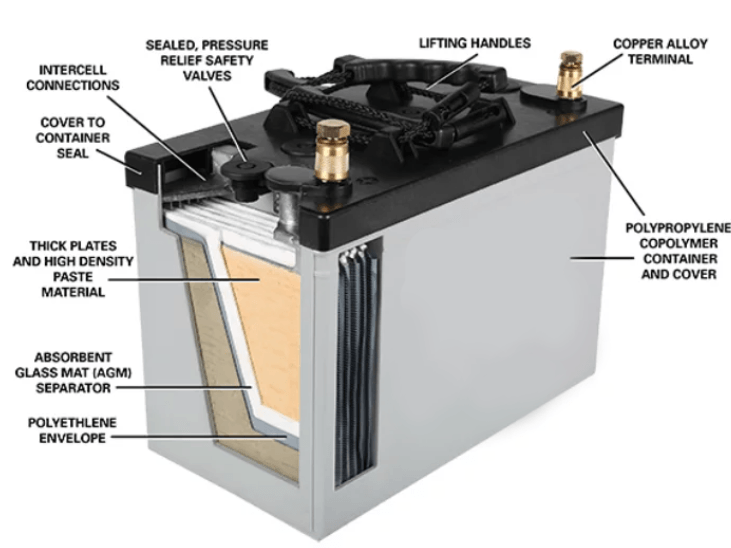

AGM battery

AGM stands for Adsorbent Fiberglass Separator Technology. The AGM battery adopts a lean liquid design. The electrode plate is not immersed in the electrolyte. Except for a part of the electrolyte inside the electrode plate, most of the electrolyte is absorbed on the porous glass fiber separator. The plates are fully in contact with the electrolyte. The separator keeps a certain proportion of the pores from being occupied by the electrolyte, which is to provide a channel for the oxygen evolved from the positive electrode to move to the negative electrode, so as to ensure that the oxygen can better diffuse to the negative electrode and recombine to form water.

Using AGM technology, on the one hand, can effectively prevent electrolyte stratification, thereby increasing the deep cycle life of the battery (which can reach 3 times that of ordinary batteries) and service life; on the other hand, due to the lower resistance of the AGM separator, it has Better low temperature performance.

Can a car without start-stop function be replaced with a normal battery?

The answer is definitely "NO"

Although some cars do not have a start-stop function, there are on-board electrical appliances such as refrigerators, coffee heaters, DVD video and television in the rear seat that need power supply, and it is not feasible to use ordinary batteries. Some people in the battery industry have tested the use of ordinary batteries instead of AGM batteries, and the results were scrapped in 3-6 months.

Compared with EFB batteries, AGM batteries have better deep cycle characteristics and can meet the application requirements of vehicles with start-stop systems, energy recovery systems, and high-end luxury cars. The EFB has the characteristics of low cost and wide temperature range, and its overall performance can meet the needs of entry-level start-stop systems.

As for the AGM vent plug and EFB vent plug, click here to view!

--End--