Differences between PE battery separator and other separators (2)

The time required for the PVC separator, PE separator, rubber separator, and PP separator to achieve stable resistance is different. This is mainly due to the different main materials used for the separator, and the different time it takes for the separator to be completely wetted by the sulfuric acid solution. Different ratios and apertures, the PP separator takes the shortest time to stabilize the resistance, the PE separator takes the longest time, the PVC separator and the rubber separator are in the middle, and the PVC separator takes a slightly shorter time than the rubber separator.

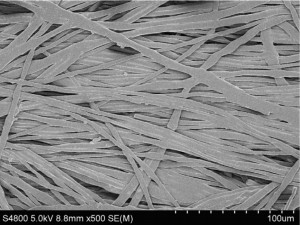

The main reason is that the PP separator has the largest pore size and the highest porosity, and the separator is hydrophilically treated with surfactants. The time required for the separator to be completely wetted by the sulfuric acid solution is the shortest. The plate resistance is stable in a short time; the PE separator takes the longest time because its pore size is the smallest, and the air in the small hole hinders the wetting of the separator by the sulfuric acid solution, and it takes a long time for complete wetting, but due to the PE separator is the thinnest, once fully wetted, the shortest path taken by ions to migrate between electrodes, thus the smallest resistance.

(PE separator)

(PE separator)

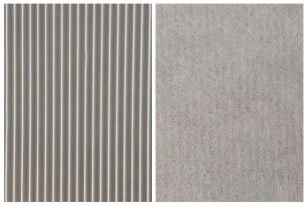

The PVC separator(search product, CLICK HERE) is between the two than the rubber separator. Due to the large aperture of the PVC separator, the time required is shorter and the resistance is smaller. The selection of materials is the most important hurdle. The reason why many partitions have such or other differences is mainly due to the difference in materials. The material of PE Separator is different from the traditional separator in the past. Its main material It is polyethylene, silica, process oil and other additives. High-quality ultra-molecular-weight polyethylene has qualitatively improved the mechanical properties and anti-aging ability of the separator.

Silicon, on the other hand, determines its porosity. With a relatively high porosity, there may be some meaning of the existence of the porosity. In fact, the separator itself is an insulator, but because of the porosity, it can conduct electricity, and the reason why the PE separator(search product, CLICK HERE) can have a relatively high porosity Thanks to the silicon contained in the material. In addition, the holes it has often have the characteristics of relatively small apertures.

The wettability of PVC battery separator, rubber separator and PE battery separator is significantly higher than that of PP separator, and PP separator has poor hydrophilic wetting ability. The resistance increase is high, and while the PVC, rubber, and PE separators are all rewettable, they rewet at a significantly lower rate than the first, and the rates vary widely.

( PVC-SiO2 battery separator)

( PVC-SiO2 battery separator)

This is mainly because the resins used in the other three resin separators are hydrophobic except for the rubber separators, and the hydrophilicity of the separators is provided by the added surfactant. Dissolved in the sulfuric acid solution from the separator, the PE battery separator contains a large amount of silica, which has a strong adsorption capacity for surfactants and less loss. Due to the small pore size of the PE battery separator, it takes a long time for complete wetting;

The PVC battery separator is sintered at high temperature, the combination of surfactant and PVC resin is stronger, and the loss is also less, and the surface tension of PVC resin is higher than that of PP; PP separator is impregnated with surfactant solution, and the surfactant is only Adsorbed on the surface of PP resin, the impregnation loss of sulfuric acid solution is very high, the hydrophilicity of PP resin is poor, the hydrophilic wettability of the separator is very poor, and the resistance is high.

--End--