PE Battery Separator

Brand: JHTD

Product origin: China

Delivery time: 10 working days

Supply capacity: Sufficient capacity, can meet the needs of any well-known large customer

- PE battery separator has higher pore volume

- PE battery separator has lower electrical resistance

- PE battery separator has lower acid displacement

- Optimal pore size distribution for controlled oxygen transfer

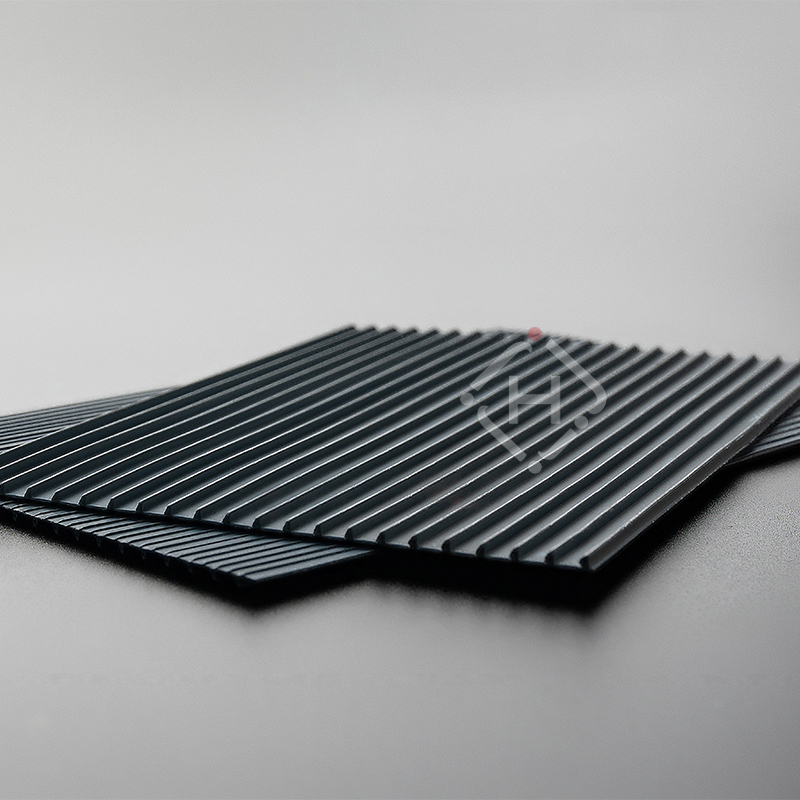

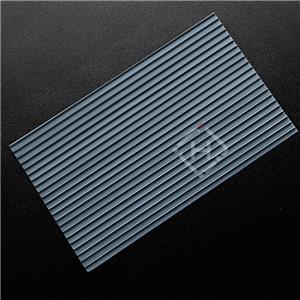

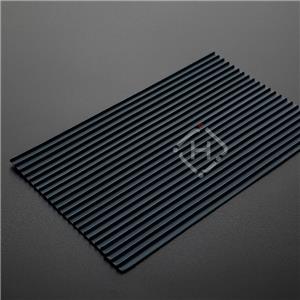

PE Battery Separator (sheet)

Introduction

Ribs on both sides of the separator increased the mechanical strength and stiffness of the battery separator. It can reduce the separator deformation caused in the process of battery assembly and avoid the direct pressure and lamination of the plate on the separator substrate, so as to effectively remove or reduce the thermal oxidation problems of PE separator and lead to dendrite penetration problems.

Want to see PE+GM separator? Click here!

Feature

- Higher pore volume

- Lower electrical resistance

- Lower acid displacement

- Optimal pore size distribution for controlled oxygen transfer

Overview

Quick Details

Automotive PE Battery Separator for Car Battery

| Brand Name: JHTD | O/W Oil Content: 12%≤Total≤18% |

| Place of Origin: China | Moisture Content: ≤3.0% |

| Puncture Resistance: ≥8 N | Dimension Stability: ≤1.0% |

| Elongaton (CMD): ≥300% | Wetting Time: ≤60 s |

Porosity: ≥55% | Acid Weight Loss: ≤4.0% |

| B/W Oil Content: ≥8% | Electrical Resistance: ≤0.0010Ω.d㎡ |

Industrial PE Battery Separator for Lead Acid Storage Battery

| Brand Name: JHTD | O/W Oil Content: 12%≤Total≤18% |

| Place of Origin: China | Moisture Content: ≤3.0% |

| Model Number: Separator sheet | Dimension Stability: ≤1.0% |

| Battery Size: Lead Acid Battery | Wetting Time: ≤60 s |

| Elongaton (CMD): ≥300% | Acid Weight Loss: ≤4.0% |

| Electrical Resistance: ≤0.0015Ω.d㎡ | Fe Content: ≤0.010 |

| Porosity: ≥55% | Usage: Industrial |

| B/W Oil Content: ≥8% | Size: General / Customized |

Specification

Width(mm) | O/A Thickness(mm) | B/W Thickness(mm) | Dorsal Rib Thickness(mm) |

116-126 | 0.7-1.4 | 0.2-0.25 | 0.1/0.25 |

155-165 | 0.7-1.6 | 0.2-0.25 | 0.1/0.25 |

No. | Item | Unit | Specification |

1 | B/W Thickness | mm | 0.2-0.25(including 0.1 mm back ribs) |

2 | Resistance value | Ω.dm2 | ≤0.0012 |

3 | Porosity | % | 60±5 |

4 | Wet-out Rate | Sec. | ≤30 |

5 | Puncture | Kg | 0.8 |

6 | CMD Elongation | % | ≥300 |

7 | Oil content | % | 12-18 |

Battery separator, lead acid battery separator membrane, lead acid battery separator flim, lead acid battery separator manufacturer, china battery separator, pe separator, polyethylene separator PE separators are highly suitable for New generation batteries which have replace the old sintered PVC separators as they improve overall performance and life of batteries which are compact and have high energy density. Microporous polyethylene (PE) separator is the abbreviation for the microporous polyethylene separator which enjoys the markedadvantages over its predecessors(like PVC and AGM separator). With the performance of smaller pore size, higher porosity, high chemical purity and high oxidation, it can work properly in the temperature range of -40ºC~80ºC. PE separator can be in sheet and pocket size and applied on starting battery, deep-circuit battery, industrial battery and maintainer-free battery. With the glass fiber mat frame, PE separator possesses the excellent anti-vibration for rough road.

FAQ

Q1:Is there back mini rib?

It depends on customer’s requirement. For thickness more than 1.3 mm, there must be back mini rib.

Q2: What is the rib style of the separator?

We can communicate according to customer’s drawing or picture of separator.