PE battery separator reduces service life under wet conditions

- By: JinHan

- Oct 12,2022

follow us

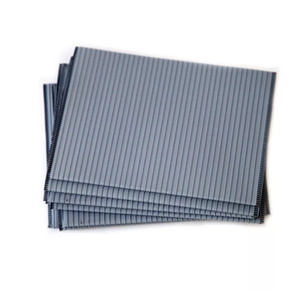

▇ PE battery separator has many effects on the performance of lead battery. Every improvement of separator quality is accompanied by the improvement of lead battery performance. The main function of PE battery separator is to prevent short circuit between positive and negative electrodes, but it cannot significantly increase the internal resistance of the battery. PE battery separator is mainly used to prevent short circuit between positive and negative electrodes, but it cannot significantly increase the internal resistance of the battery. Therefore, the separator should be porous, allowing free diffusion of electrolyte and ion migration, and has a relatively small resistance. PE battery separator shall not reach the opposite electrode plate through fine holes, that is, the hole diameter shall be small, the number of holes shall be large, and the total area of the gap shall be large.

▇ When used under wet conditions, the negative plate is easy to oxidize, and the initial charging time is long. It can not be used for dry loaded lead batteries. In particular, the wooden separator is not resistant to oxidation and corrosion in sulfuric acid, resulting in short battery life. In order to improve the service life of lead acid battery, it is proposed to use wood separator and glass wool separator together to double the service life of the battery; The main function of PE battery separator is to enable the ion flow between electrodes, with high porosity; The surface area and good wettability are characterized by being able to absorb a large amount of electrolyte, and having good tensile strength to ensure that the separator will not be punctured by sharp edges or small particles during the assembly process during the production of batteries.

▇ PE battery separator prevents the positive and negative electrode plates from contacting each other and causing internal short circuit of the battery, making the battery tightly assembled and reducing the battery volume; In order to prevent deformation, bending and active substances falling off of the electrode plate; Store the necessary amount of electrolyte in the porous separator between the plates to ensure high conductivity and battery reaction requirements; Prevent some substances harmful to the electrode from migrating and diffusing through the separator. To ensure that the separator can function smoothly in the battery, there must be certain requirements for the separator itself. The material of PE battery separator itself is an insulator, but when it is made into a separator, it must be loose and porous, and can absorb and store a large amount of electrolyte solution.

--End--

English

English Russian

Russian Portuguese

Portuguese Arabic

Arabic Bangla

Bangla Indonesian

Indonesian