How to Choose High-Quality PE Separator

- By: JinHan

- Aug 05,2024

follow us

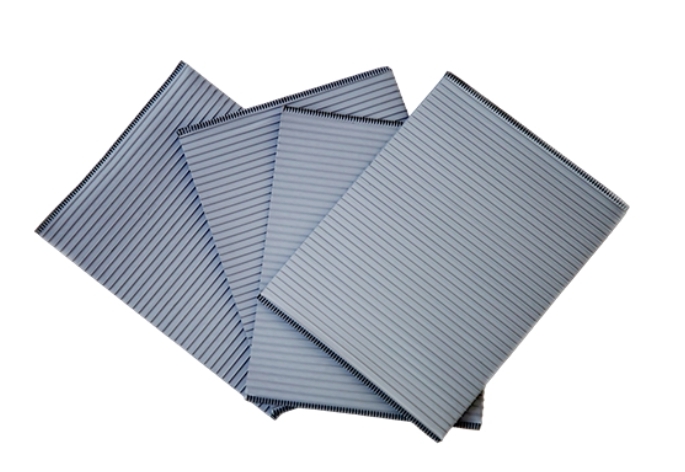

Selecting high-quality PE (polyethylene) separator requires careful consideration of several factors to ensure they meet the demands of your specific applications. The first aspect to focus on is the material quality. High-grade polyethylene offers better durability, chemical resistance, and flexibility, which are essential for the performance and longevity of the sheets. It's important to check that the manufacturer adheres to industry standards and certifications, guaranteeing the reliability of the material used.

Uniformity in thickness is another critical element. The strength and stability of the sheets largely depend on having a consistent thickness throughout. Inconsistent thickness can lead to weaknesses and potential failures in applications such as battery separators, packaging, and construction. Therefore, it’s advisable to measure the thickness at multiple points to ensure uniformity.

Chemical resistance is a key property, especially for PE separator used in environments exposed to various chemicals. High-quality sheets should be able to withstand acids, alkalis, solvents, and other corrosive substances without degrading. Reviewing the chemical resistance specifications provided by the manufacturer is crucial to ensure the sheets will perform effectively under the expected conditions.

Temperature tolerance is also vital. PE separator should maintain their structural integrity and properties across a wide range of temperatures. This is particularly important for applications involving extreme conditions, such as high-temperature industrial processes or cold storage. Understanding the operating temperature range of the sheets helps in choosing ones that will remain stable and functional under your specific environmental conditions.

Mechanical strength is another aspect to evaluate. The separator should be capable of withstanding mechanical stress and pressure without tearing or deforming. High tensile strength and impact resistance are indicators of robust and durable materials. These properties are particularly important for applications where the sheets will be subjected to significant physical forces.

The surface finish of the PE separator can affect their performance in certain applications. For instance, a smooth surface may be necessary for applications requiring low friction, while a textured surface might be preferred for better grip and handling. Choosing the appropriate surface finish based on the specific requirements of your application can enhance the performance of the sheets.

Selecting high-quality PE separator involves a thorough evaluation of material quality, thickness and uniformity, chemical resistance, temperature tolerance, mechanical strength, moisture absorption, surface finish, manufacturer reputation, cost-effectiveness, and customization options. By carefully considering these factors, you can ensure that the PE separator sheets you choose will meet the demands of your application and provide reliable performance.

Need to purchase products , please click here to view!

English

English Russian

Russian Portuguese

Portuguese Arabic

Arabic Bangla

Bangla Indonesian

Indonesian